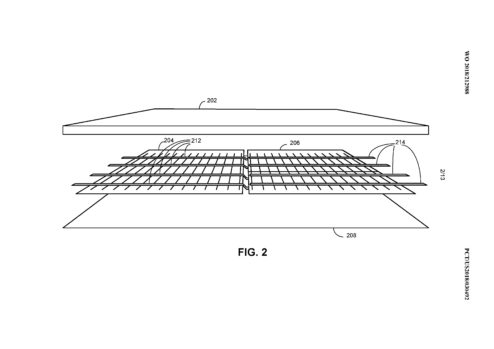

If recent announcements by Tesla are any indication, the Solar Roof tiles will see a production ramp next year. Unveiled in October 2016, the Solar Roofs, which are PV modules that have the appearance of traditional roofing materials, were received warmly, with Tesla noting that the product was sold out “well into 2018” within the first few weeks of reservations being opened.

One of these reservation holders was Amanda Tobler. After initially living in a rental house from 2002 to 2004, Amanda and her family moved to a CA townhousein 2004, where they stayed for 12 years. The Toblers attempted to get solar panels installed on their townhouse then, though they were unsuccessful due to the area’s homeowners association prohibiting rooftop solar systems. Things changed in 2016, when Amanda and her family moved to a two-story suburban home in the Bay Area. This time around, the Toblers was free to add a solar system for their house.

The home that the family acquired, which was built in 1965, had an aging stamped metal roof that was nearly ready for replacement. In an emailed statement to Teslarati, Amanda noted that when they heard about the Solar Roof tiles, her family immediately thought that the product would be a perfect fit for their new home. Within days of Tesla opening reservations for the shingles in May 2017, the Toblers put down their $1,000 deposit.

In July 2017, Tesla sent someone over the home to conduct a site survey. As a way to determine the size of the PV system which would best fit the Toblers’ needs, Tesla asked for copies of past utility bills. Amanda notes that her family actually consumes a fair amount of power every month, especially since they charge two plug-in vehicles — a Nissan Leaf and a Chrysler Pacifica Hybrid — on a consistent basis. Considering the family’s average energy consumption, Tesla opted to install a 9.9 kW Solar Roof system on the house, paired with one Powerwall 2 unit.

![Tesla Solar Roof residential 3 [Credit: @Toblerhaus/Twitter]](data:image/svg+xml,%3Csvg%20xmlns='http://www.w3.org/2000/svg'%20viewBox='0%200%20317%20185'%3E%3C/svg%3E)

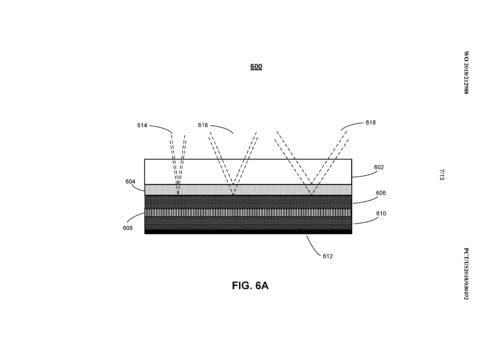

A Solar Roof tile installation on a residential unit. [Credit: Amanda Tobler]

![Tesla Solar Roof residential 2 [Credit: @Toblerhaus/Twitter]](data:image/svg+xml,%3Csvg%20xmlns='http://www.w3.org/2000/svg'%20viewBox='0%200%20317%20237'%3E%3C/svg%3E)

A Solar Roof tile installation on a residential unit. [Credit: Amanda Tobler]

![Tesla Solar Roof residential 1 [Credit: @Toblerhaus/Twitter]](data:image/svg+xml,%3Csvg%20xmlns='http://www.w3.org/2000/svg'%20viewBox='0%200%20670%20426'%3E%3C/svg%3E)

A Solar Roof tile installation on a residential unit. [Credit: Amanda Tobler]

The Toblers’ home fitted with Tesla’s “Textured” Solar Roof tiles. [Credit: Amanda Tobler]

(adsbygoogle = window.adsbygoogle || []).push({});

Tesla only manufactures two variants of the Solar Roof tiles today — Textured and Smooth — though other options such as Tuscan and Slate are due to enter production in the near future. In Amanda’s case, she opted for the Textured Solar Roof variant. Just as luck would have it, the Toblers’ home ended up becoming the first residential Solar Roof installation in the country, partly due to the roof’s simple design and the house’s proximity to the Fremont factory.

“I was told that we were chosen because we live in the Bay Area, which is convenient to the Tesla factory in Fremont. Additionally, we have simple roof lines, and they wanted a straightforward install in the beginning,” Amanda stated.

The Solar Roof installation took place in early March 2018. The entire process took about three weeks to complete, partly due to rains and Tesla’s discovery of a cedar shake roof underneath the house’s metal roof. Despite her house being built in 1965, and despite Tesla having to haul away two roofs instead of one, Amanda notes that the installation process, including the setup of the Powerwall 2 unit, remained seamless nonetheless. Even the permits for the solar system, which are required for homeowners, were handled by the electric car maker.

“Tesla took care of all permitting and getting permission to operate the solar roof. We did e-signing for plenty of documents in this process, but I didn’t have to complete any of them outside of providing a signature and date,” Amanda noted.

The Toblers were permitted to activate their Solar Roof tiles two weeks after the project was complete. Considering that the roof covered around 2,000 square feet, and that 40% of the tiles were solar, Amanda notes that the $62,000 she paid for the 9.9 kW system was not too far from the cost of a new premium roof and conventional solar panels. That said, she did mention that if her house didn’t really need new roofing, she probably would have opted for traditional solar panels instead to save on costs. Nevertheless, the homeowner pointed out that the aesthetics and functionality of the Solar Roofs have been worth the investment so far.

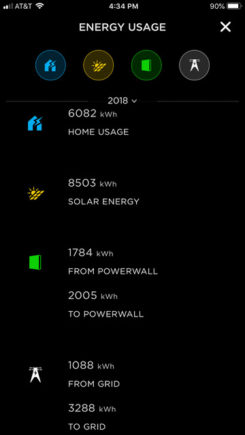

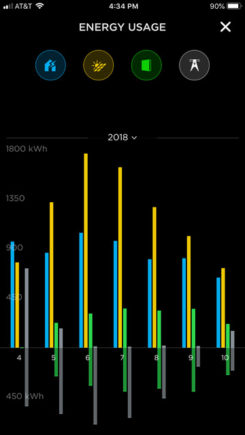

The average stats for the Toblers’ Solar Roof over the past seven months. [Credit: Amanda Tobler]

The average stats for the Toblers’ Solar Roof over the past seven months. [Credit: Amanda Tobler]

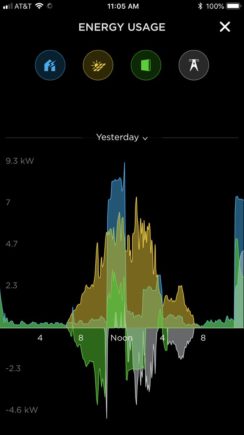

A sample of the Solar Roof tiles’ daily stats. [Credit: Amanda Tobler]

A sample of the Solar Roof tiles’ daily stats. [Credit: Amanda Tobler]

At its peak, the Toblers’ Solar Roof tiles provided enough power for the family’s needs. [Credit: Amanda Tobler]

“The main value is that we got the new roof we needed and the solar we wanted in a slick package. Of course, the product is considerably more expensive than regular solar panels—you’re getting a roof and solar panels. If you consider the cost of purchasing a high-end roof with solar panels in the Bay Area, the cost wouldn’t be that far off from the cost of the Solar Roof.”

The Solar Roof tiles have held up well over the past seven months since the system was installed. The day after the Solar Roof tiles were activated, the homeowner woke up to her roof producing 4 kW of power, with 0.4 kW flowing straight into the house and the rest charging her Powerwall 2. At its peak during summer in June and July, the Solar Roof tiles were producing about 60 kWh in one day, which was more than enough to power the Toblers’ house and their two plug-in vehicles. As the days got shorter and more overcast amidst the approaching winter, though, the Solar Roof tiles generated less energy, now producing about 20 kWh a day.

Amanda’s observations with her Solar Roof tiles echo those of another Solar Roof early adopter, Tri Huynh from Northern CA. In an interview with Alex Guberman of E for Electric earlier this year, Tri noted that his Solar Roof installation, which covers his 1,000 square foot roof, produces about 3 kW during days when skies are overcast. While the generated power is not enough to charge his three Powerwall 2 batteries, Tri noted then that his Solar Roof helps him lower his electricity bill nonetheless.

When Elon Musk unveiled the Solar Roof tiles, he candidly remarked that the shingles, if they prove successful, could end up being a “Keeping up with the Joneses” situation. In Amanda’s case, her Solar Roof had attracted a notable amount of curiosity from her neighbors, especially when the system was being installed. Once it was operational, interested members of her community also paid a visit to Toblers’ home to learn about how the Solar Roof worked. That said, the homeowner notes that the attention her Solar Roof attracts has mellowed down since.

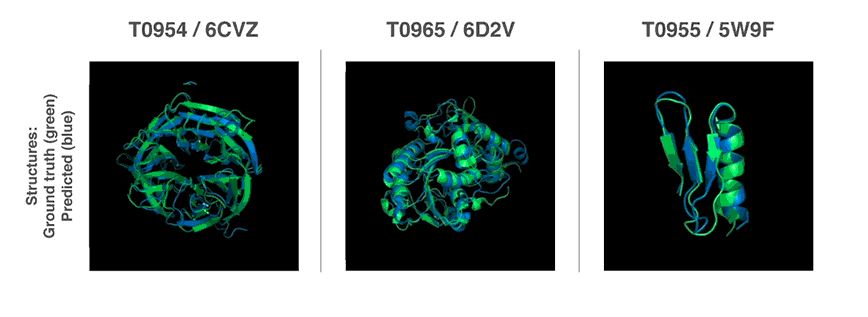

Tesla’s Solar Roof variants — Smooth, Textured, Tuscan, and Slate. [Credit: Tesla]

While the Solar Roof has performed well since it went online earlier this year, Amanda notes that the system still has some room for improvement. Her Powerwall 2, for one, faults about once a month, which makes the battery storage unit appear like it had lost connection with the system. So far, the Toblers have been manually resetting the Powerwall 2 to address the fault. In the event that the family is not home, Amanda states that the system eventually detects the error and automatically resets the Powerwall 2 after about four hours. Amanda describes these faults as a “minor annoyance,” particularly since the rest of the system has been consistently operating smoothly.

Tesla’s energy business, led by industrial-grade batteries like the Powerpack and novel residential products like the Solar Roof, is expected to see notable growth in the coming years. Billionaire investor Ron Baron, for one, estimates that Tesla Energy would likely be worth $500 billion on its own by 2030, equal to his estimates for the company’s more well-known electric car business. Considering that Tesla’s electric cars and energy products form an ecosystem of renewable solutions, the adoption of products like the Solar Roof would likely be as quick as the products’ production ramp.

During Tesla’s third-quarter earnings call, Elon Musk explained that the production of the Solar Roof is taking longer than expected due to the tiles’ long development cycle. The Tesla CEO did state, though, that Solar Roof production should see a production ramp in 2019. This was highlighted in a later announcement on Twitter, with Musk listing the solar tiles as one of Tesla’s high-priority products, directly after the Model Y. With Tesla focusing on both its electric car and energy business in 2019, the number of customers buying into the full Tesla ecosystem would likely increase. Amanda, for her part, notes that her family might do just that.

“The success of the vehicles played a big part of us choosing to trust Tesla in being a part of early solar roof adopters. It is very possible that we’ll become Tesla vehicle owners in the future,” she said.

![Tesla Solar Roof residential 3 [Credit: @Toblerhaus/Twitter]](https://www.teslarati.com/wp-content/uploads/2018/03/Tesla-Solar-Roof-residential-3-317x185.jpg)

![Tesla Solar Roof residential 2 [Credit: @Toblerhaus/Twitter]](https://www.teslarati.com/wp-content/uploads/2018/03/Tesla-Solar-Roof-residential-2-317x237.jpg)

![Tesla Solar Roof residential 1 [Credit: @Toblerhaus/Twitter]](https://www.teslarati.com/wp-content/uploads/2018/03/Tesla-Solar-Roof-residential-1-670x426.jpg)