Panasonic Corporation President Kazuhiro Tsuga effectively debunked speculations alleging that the Japanese company’s relationship with American electric car maker Tesla is on the rocks. During a recent Q&A session, Tsuga explained the dynamic between Tesla and Panasonic, as well as his insights about the idea of the electric car maker utilizing another battery supplier for Gigafactory 3.

The relationship between Tesla and Panasonic was thrown into question following a report from the Nikkei Asian Review last month, which alleged that the Japanese company was freezing its investments in Gigafactory 1. Tesla responded to the report, stating that there is far more output to be gained by improving the existing production lines in the Nevada-based factory. Elon Musk took to Twitter as well, stating that Panasonic’s lines at Gigafactory 1 are only operating at ~24 GWh per year despite having a theoretical capacity of 35 GWh.

Musk’s tweets were promptly interpreted as a “public battle” with Panasonic. Craig Irwin of Roth Capital Partners noted that “Tesla and Panasonic need couples counseling ASAP,” adding that “this is looking like a much more acrimonious relationship.” Tsuga, for his part, mentioned that Tesla and Panasonic maintain a “very good relationship between ourselves” during the Q&A session. Explaining further, the Panasonic President pointed out that the two companies have always been candid with each other, especially when it comes to investments in facilities such as Gigafactory 1.

“(In) the earlier session with the media, there was a question as to (whether) we have (a) bad relationship, (or if) we’re not getting along with Tesla. Well, we are making sure that we have a partnership relationship, not a supplier relationship. And since we are partners, we are very frank and candid and honest to each other. So on this battery business, as for the investment facilities — for the facilities that we have invested, can we maintain the battery operation with the orders coming in? From Tesla’s point of view, with the batteries being supplied, they can manufacture their vehicles on a full capacity basis.

“Unless that is established, this would not be a win-win relationship. In the past, what hurt us (was) that we were told that ‘This is the capacity you’ll need,’ but we couldn’t sell that much batteries. That’s the worst case. And that sense, Tesla is purchasing everything that we manufacture. And they have not just the electric vehicles but they do have the storage batteries as well, and they are asking for the capacity increase all the time. And therefore, we have capacity but not being produced. That situation is not envisioned for Gigafactory for now. So I think we have a very good relationship between ourselves,” Tsuga said.

Other concerns that were brought forward on the heels of the Nikkei report were Panasonic’s speculated issues about Tesla’s potential local battery partner in Gigafactory 3. Tesla is speculated to utilize a local battery supplier for the Shanghai-based electric car production facility, a strategy that analysts such as Cairn Energy Research Advisors managing director Sam Jaffe believed would irk Panasonic. “Tesla is starting to flirt with other battery makers in China, and Panasonic doesn’t like that,” Jaffe said in a statement to the Los Angeles Times.

Panasonic President Tsuga expressed a completely different sentiment about the topic, noting that it makes sense for Tesla to adopt a multiple supplier model for Gigafactory 3. “Now because of what happens in China, Tesla is considering a multiple supplier structure, which makes sense for Tesla maybe given the very special nature of doing business in China, and maybe they need to have that structure so as to be approved by China authority. So on the part of Tesla, they might prefer — they might start considering getting multiple suppliers, but that doesn’t mean that our relationship is being hurt and is being unstable, no. We continue to have very solid, very strong relationship with Tesla,” Tsuga said.

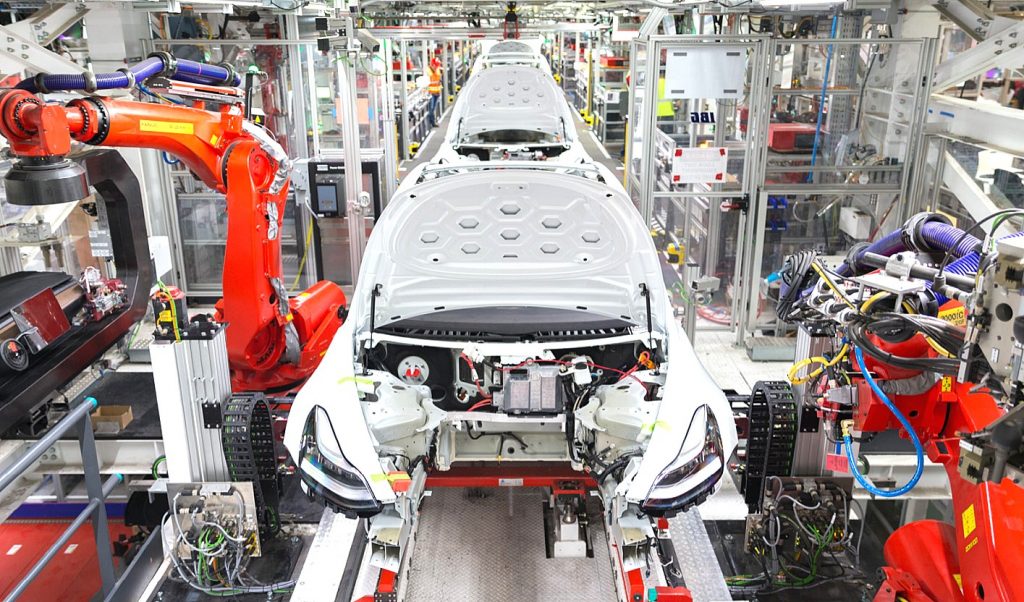

Panasonic and Tesla have been in a close working relationship for years. The Japanese company currently produces the battery cells for Tesla’s vehicles, from the 18650 cells used in the Model S and Model X to the 2170 cells utilized in the Model 3. Considering the recent statements of the Panasonic President, as well as Tesla’s ramp of its existing and upcoming products, it appears that the two companies’ partnership will likely remain strong for some time to come.

<!–

–>

var disqus_shortname = “teslarati”;

var disqus_title = “Tesla battery partner Panasonic debunks rumors about alleged Gigafactory 1 conflicts”;

var disqus_url = “https://www.teslarati.com/tesla-panasonic-defends-gigafactory-1-partnership/”;

var disqus_identifier = “teslarati-104128”;