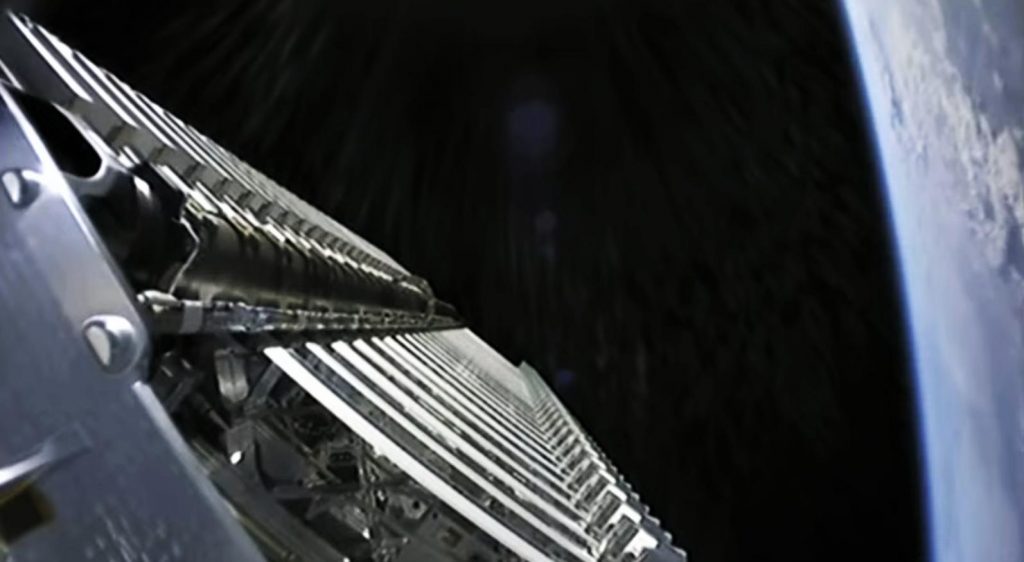

SpaceX support ship GO Discovery has successfully completed its third trip from Florida to Texas, ferrying additional rocket production hardware to the company’s fast-expanding South Texas Starship factory.

Captured on arrival by local spaceflight fan and observer SPadre (@SpacePadreIsle), the SpaceX ship entered Port of Brownsville on March 22nd, carrying a few minor pieces of equipment that SpaceX’s Starship factory will likely find helpful down the road. The company’s South Texas presence has undergone a meteoric period of growth in the last few months, hiring hundreds to staff a Starship factory that is now churning out rocket parts on the rugged South Texas Gulf Coast.

While it’s more a question of “when” than “if” the birth of a global pandemic will come to seriously impact SpaceX’s supply chain and general operations, South Texas included, the company’s Starship factory has yet to show any signs of slowing down. Facilities expansion and Starship production continues at a breakneck pace, with the latest major construction project beginning just days ago and the company’s newest rocket prototype speeding towards completion. As such, the hardware delivered from Florida could see use in a matter of days, although SpaceX may be moving so quickly that it’s already somewhat redundant.

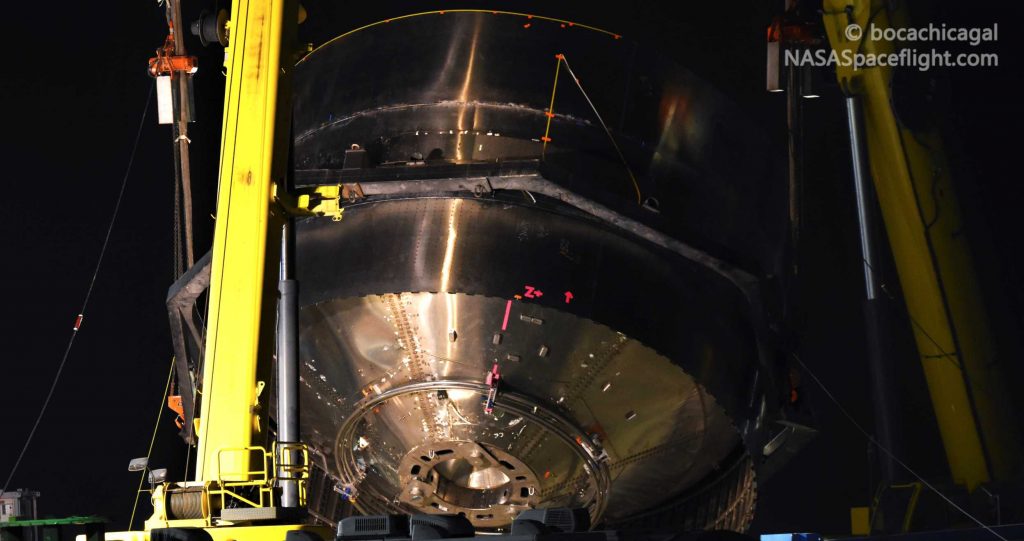

The stands were loaded onto GO Discovery in Port Canaveral, Florida for a March 16th departure and the ship took six days to complete its ~2100-km (1300 mi) journey to Texas. This is the third time SpaceX has shipped hardware from its Florida Starship factory – temporarily shuttered since December 2019 – to its Texas Starship factory, which continues to expand and build rockets at an incredible rate.

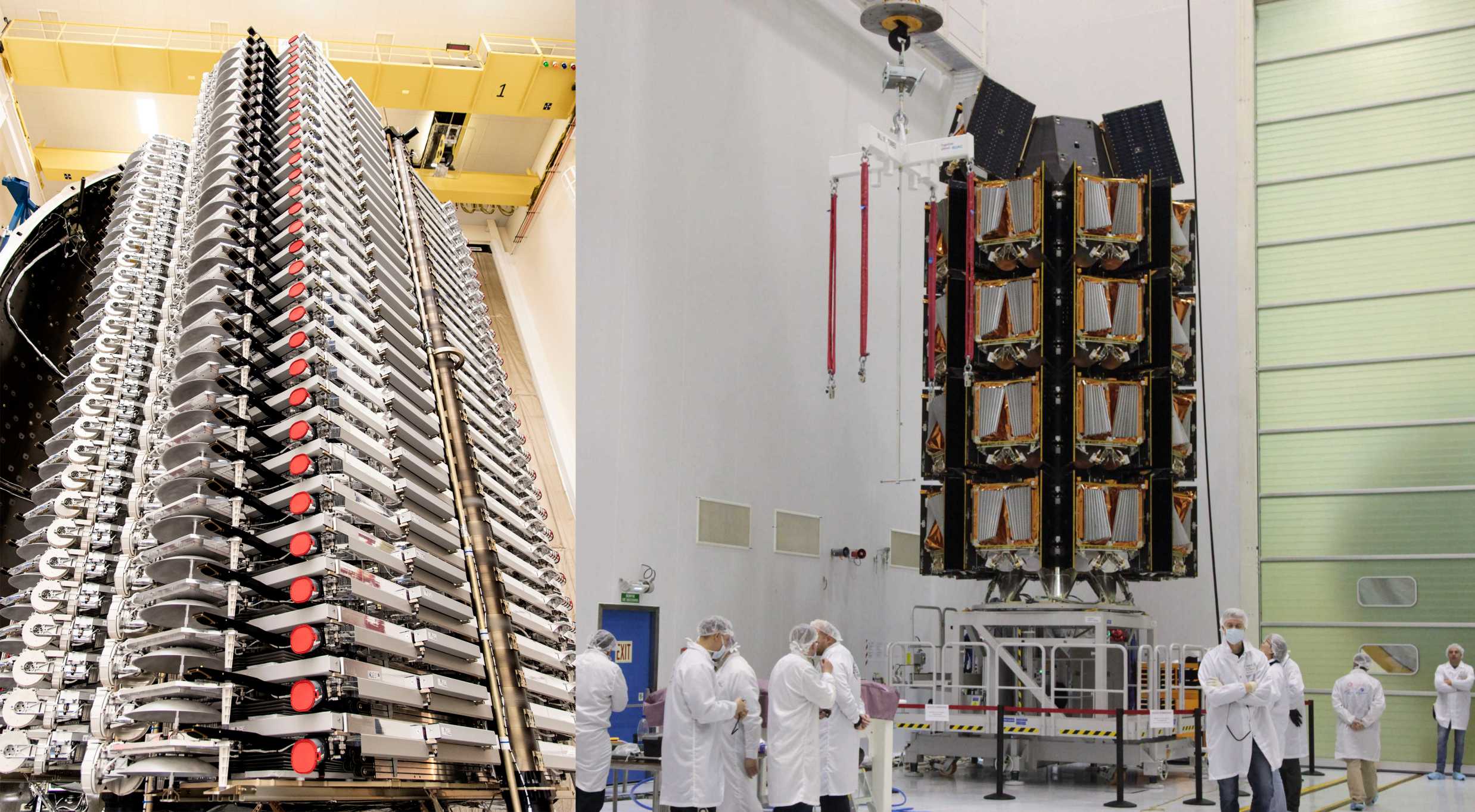

Just a few hours after arrival, SpaceX workers removed GO Discovery’s cargo and prepared it for transport, moving the hardware to its facilities around 12pm CDT (UTC-5). Curiously, SpaceX immediately transported two large steel stands past its Starship factory and to its launch and test facilities, situated about a mile down the road.

The company has used numerous similar stands and even completed several new ones over the last several months. The steel structures serve as work stands that offer great access and easy mobility, as well as testing mounts for several Starship tank prototypes SpaceX has tested this year. Given that SpaceX recently passed its first tank test unscathed and is in the midst of completing assembly of the third full-scale Starship prototype, it appears that the two stands shipped from Florida will populate the company’s reserves instead of immediately entering service.

SpaceX could be just a week or two away from completing its third full-scale Starship prototype and proceeding into pressure testing. If successful, the massive vehicle could become the first of its kind to attempt wet dress rehearsals (WDRs) – using real, explosive propellant – and, soon after, Raptor engine static fires.

(adsbygoogle = window.adsbygoogle || []).push({});

<!–

–>

var disqus_shortname = «teslarati»;

var disqus_title = «SpaceX Texas Starship factory accepts third Florida hardware shipment»;

var disqus_url = «https://www.teslarati.com/spacex-starship-factory-third-florida-shipment/»;

var disqus_identifier = «teslarati-133992»;