The polarizing Tesla Cybertruck has caught the attention of automotive industry veteran Sandy Munro, who offered his honest opinion on the electric car manufacturer’s all-electric pickup during an interview with E for Electric‘s Alex Guberman.

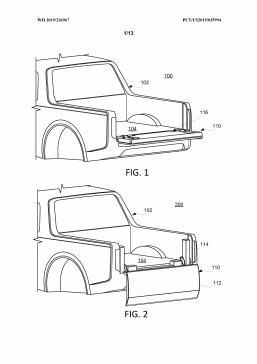

Munro’s initial thoughts had to deal with the design and aesthetics of the truck. Citing the flat panels and simplistic design, Munro feels the vehicle will be relatively easy to build and produce. This will end up making its production rate higher than vehicles whose design contains contours. “The truck itself, because its all flat panels and whatnot, its a much much easier product to manufacture than anything that’s got lots of curves and whatnot,” Munro said.

While Elon Musk gave ample warning about the design of the Cybertruck, the real-life look of the vehicle was met with mixed reviews anyway. Nevertheless, the quarter of a million pre-orders the pickup received were enough to show that people were interested in its hip and unique design.

A product of Detroit’s rich history in automotive production, Munro currently drives a Jeep Rubicon, a vehicle he purchased for his hobby of off-roading. “The only relaxing thing I do is run over plants and be probably nasty to nature. So this kind of a vehicle to me is pretty interesting. I’m very happy that Tesla decided to put out something like this,” he said.

It is assumed that Tesla was aiming to not only release a vehicle that would compete with the traditional, petrol-powered trucks, but also would appeal to those who have an interest in the outdoors. Fellow electric car maker Rivian will begin producing its R1T pickup truck next year, and the company has geared its products toward people with hobbies that include camping and off-roading. While it is unknown if Tesla wanted to produce a truck that would compete with the ruggedness of the R1T, it is apparent that the company is interested in reaching out to the outdoor crowd, especially with the release of its electric ATV.

Guberman touched on the battery technology Tesla would utilize for the Cybertruck. After mentioning Tesla’s acquisition of Maxwell Technologies in late 2019, Guberman contributed this business move to the impressive 500+ mile range of the Cybertruck’s tri-motor variant. In the past, Munro has complimented Tesla’s battery technology, which he attributes to the company’s complete focus on EVs. Munro estimates that Tesla holds somewhere around a 10-year lead in this category, an idea he expressed in a past interview with electric car enthusiast Sean Mitchell.

Munro is noted as an industry expert in the E for Electric interview, and with an extensive resume where he held positions with Ford Motor Company and Kia Motors, it is understandable why he holds this title. Munro has spoken highly of Tesla in the past and has even done a teardown of the Model 3 Long Range variant. During this analysis of the vehicle, he notes the in-house development of Tesla vehicles as the primary reason why the company continues to have such large profitability.

You can watch Sandy Munro’s complete interview with E for Electric‘s Alex Guberman below.

(adsbygoogle = window.adsbygoogle || []).push({});

<!–

–>

var disqus_shortname = «teslarati»;

var disqus_title = «Tesla Cybertruck gets honest review from teardown expert: ‹I’m very happy that Tesla…put out something like this'»;

var disqus_url = «https://www.teslarati.com/tesla-cybertruck-honest-review-sandy-munro-video/»;

var disqus_identifier = «teslarati-123491»;