Tesla has started rolling out software 2020.8.1 that includes Track Mode V2 for Model 3, third-party charging stations, improvements to Model S and Model X regenerative braking, and a host of other features.

YouTuber Tesla Raj explored the latest software update using the Model 3 Performance of Wade Anderson (@TeslaSocialC) to demonstrate features for Track Mode and discuss what’s new. The 2020.8.1 firmware includes improvements to Navigation, Driving Visualization, Bluetooth, regenerative braking, voice command reliability, third-party charging station options, plus minor updates on language support.

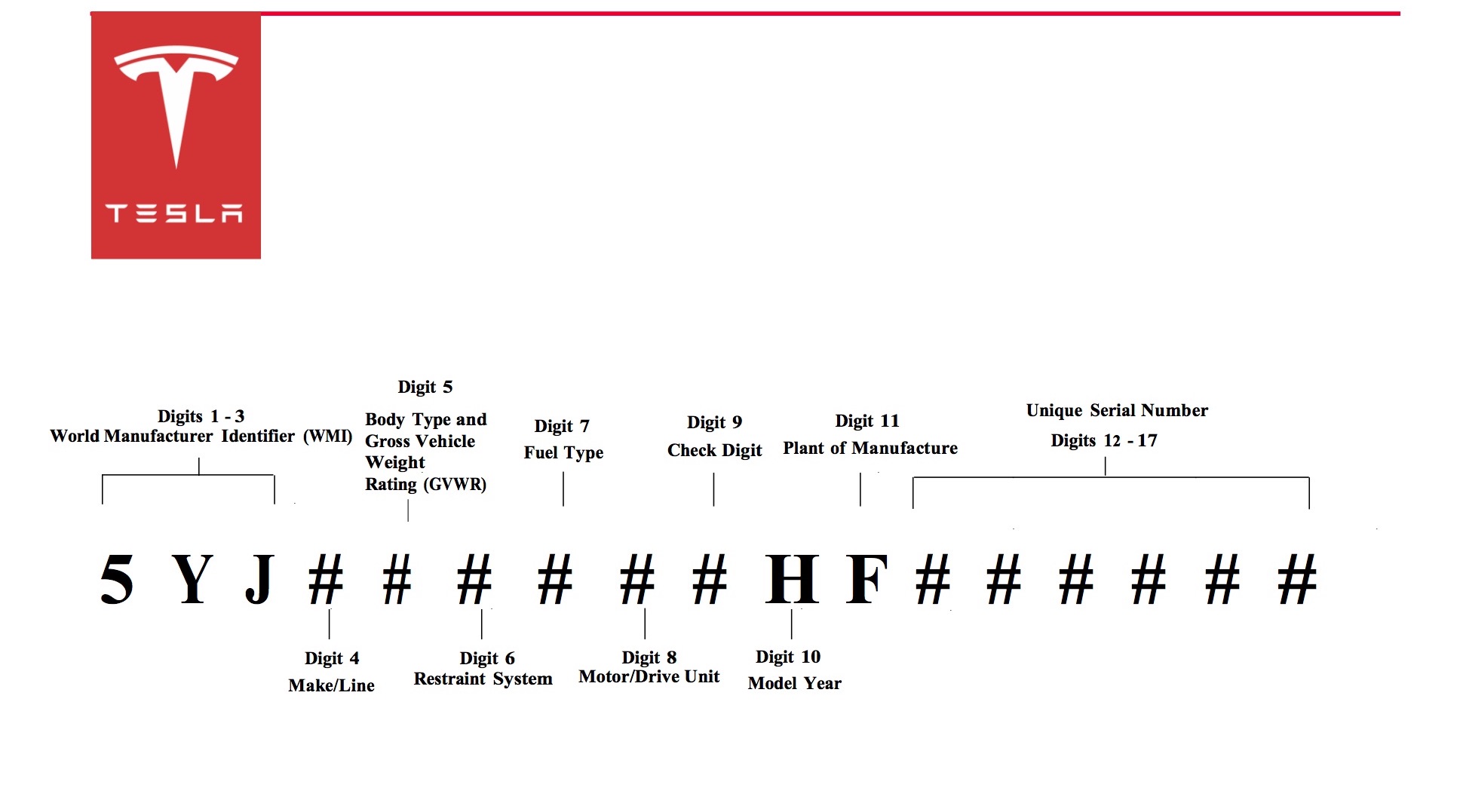

Track Mode V2 for Model 3

The latest version of the Track Mode for the Model 3 started rolling out as a free over-the-air (OTA) update earlier this week and coinciding with the launch of the Model 3 Track Package for racing enthusiasts.

Track Mode V2 gives Model 3 owners the option of customizing settings for Handling Balance, Stability Assist, Regenerative Braking, among others.

“Track Mode has been improved to make it easier to monitor the status of your car, create custom track mode settings profiles and record your track day data,” the 2020.8.1 firmware release notes read.

Tesla Raj, upon getting the latest software update, tested the Track Mode V2 on the Model 3 and switched the car to rear-wheel drive with no stability assist.

“I have never… I don’t have much experience in a Performance Model 3 but I’ll tell you one thing. My heart, lungs, and liver, and all my body parts are all here in my chest,” said Tesla Raj.

Tesla Raj and Tesla Social also switched to full front-wheel drive and then to 50-50 to feel how the car would perform.

Track Mode allows owners to create 20 profiles that perfectly suits their preferences and driving scenarios. Users can also customize the settings for a specific track.

Track Mode V2 also allows you to monitor the status of the car’s motors, brakes, and tires. The latest firmware also allows one to see a real-time accelerometer via the G-meter. Likewise, the map now includes a Lap Timer.

Model 3 owners can also save a video and other data of their driving sessions while on Track Mode. One has to assign a folder named “TeslaTrackMode” in the plugged USB flash drive where all the files would be saved. Track Mode will also store telemetry data, car status, speed, acceleration, and use of accelerator on the flash drive.

Bluetooth, Driving Visualization, And More

Tesla also tweaked how Bluetooth audio transitions from one’s phone to the car with this latest update. Now, Bluetooth connects a paired phone only after sitting in the driver’s seat and once all of the vehicle’s doors are closed.

More users can now enjoy the improved driving visualizations showing stoplights, stop signs, and select road markings, which was only available before to Tesla owners in the United States.

According to the release notes, Tesla has also improved voice command reliability even in areas with poor connectivity.

Tesla owners in select sites in the San Francisco Bay Area can now find third-party charging stations via in-car navigation. Users in other locations in the US will also be able to enjoy this feature soon.

Regenerative Braking Improvements and New Navigation for Model S and Model X

Firmware 2020.8.1 also gives Model S and Model X owners increased regenerative braking that improves the overall driving experience and increases the amount of energy actively returned to the vehicle’s battery when slowing down.

The latest update also introduces a new navigation system with improved routes, more accurate arrival times, and a more responsive instrument cluster.

The full release notes for Firmware 2020.8.1 can be found below:

Introducing new Navigation (Beta)

Only Model S and X

Introducing a new navigation system for your vehicle that provides improved routes, more accurate arrival times, and a more responsive instrument cluster view to better display upcoming maneuvers.

For China: This release also includes new maps on the touchscreen. You can now view the maps in satellite view and see nearby points of interest.

Driving Visualization Improvements

This has been added for more regions, previously just the US.

The driving visualization can now display additional objects which include stop lights, stop signs and select road markings. The stop sign and stop light visualizations are not a substitute for an attentive driver and will not stop the car. To see these additional objects in your driving visualization, tap Controls > Autopilot > Self Driving Visualization Preview.

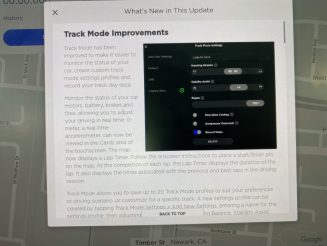

Track Mode Improvements

Only Model 3 (Performance)

Track Mode has been improved to make it easier to monitor the status of your car, create custom track mode settings profiles and record your track day data.

Monitor the status of your car motors, battery, brakes and tires, allowing you to adjust your driving in real time. G-meter, a real-time accelerometer, can now be viewed in the Cards area of the touchscreen. The map now displays a Lap Timer. Follow the onscreen instructions to place a start/finish pin on the map. At the completion of each lap, the Lap Timer displays the duration of the lap. It also displays the times associated with the previous and best laps in the driving session.

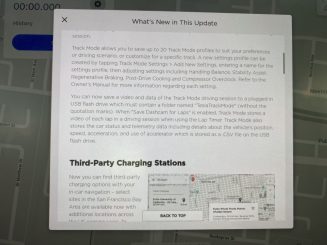

Track Mode allows you to save up to 20 Track Mode profiles to suit your preferences or driving scenario, or customize for a specific track. A new settings profile can be created by tapping Track Mode Settings > Add New Settings, entering a name for the settings profile, then adjusting settings including Handling Balance, Stability Assist, Regenerative Braking, Post-Drive Cooling and Compressor Overclock. Refer to the Owner’s Manual for more information regarding each setting.

You can now save a video and data of the Track Mode driving session to a plugged in USB flash drive which must contain a folder named “TeslaTrackMode” (without the quotation marks). When “Save Dashcam for Laps” is enabled, Track Mode stores a video of each lap in a driving session when using the Lap Timer. Track Mode also stores the car status and telemetry data including details about the vehicle’s position, speed, acceleration, and use of accelerator which is stored as a .CSV file on the USB flash drive.

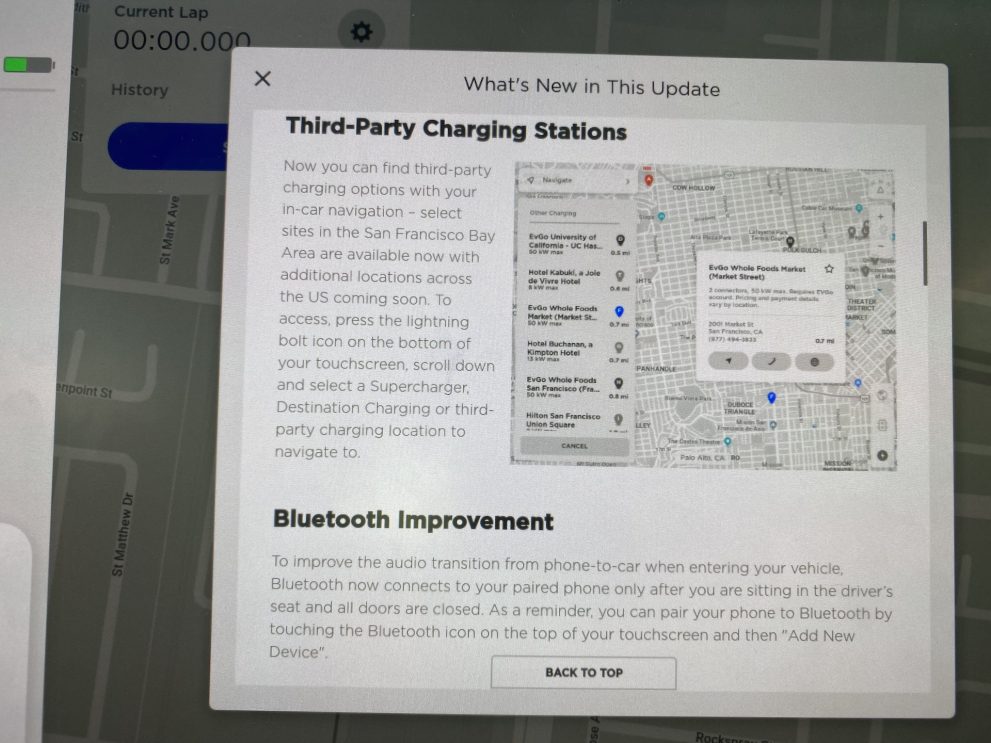

Third-Party Charging Stations

Only vehicles in California.

Now you can find third-party charging options with your in-car navigation – select sites in the San Francisco Bay Area are available now with additional locations across the US coming soon. To access, press the lightning bolt icon on the bottom of your touchscreen, scroll down and select a Supercharger, Destination Charging or third-party charging location to navigate to.

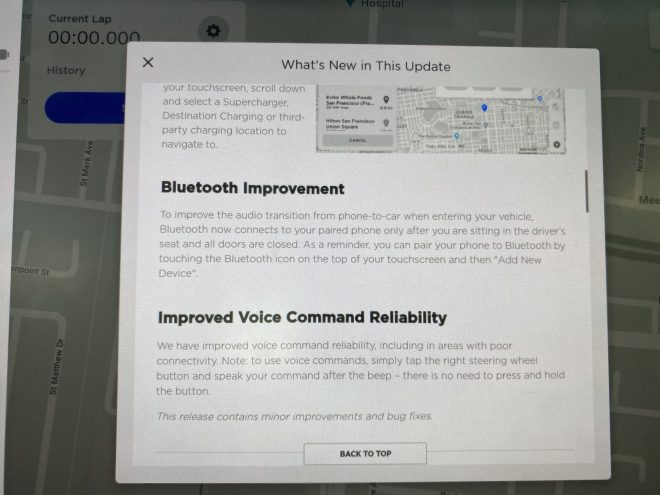

Bluetooth Improvement

To improve the audio transition from phone-to-car when entering your vehicle, Bluetooth now connects to your paired phone only after you are sitting in the driver’s seat and all doors are closed. As a reminder, you can pair your phone to Bluetooth by touching the Bluetooth icon on the top of your touchscreen and then “Add New Device”.

Regenerative Braking

Only Model S and X

Regenerative braking force has been increased to improve the driving experience and increase how much energy is actively returned to the battery when slowing down.

Improved Voice Command Reliability

We have improved voice command reliability, including in areas with poor connectivity. Note: to use voice commands, simply tap the right steering wheel button and speak your command after the beep – there is no need to press and hold the button.

Additional Language Support

Your touchscreen is now available in additional languages. To change the language, simply go to Controls > Display > Language. Please note that your vehicle must be in PARK to enable this selection.

Additional Owner’s Manual Languages

The Owner’s Manual on your touchscreen is now available in Romanian, Hungarian, Slovenian, and Hebrew. As a reminder, you can change the language of the Owner’s Manual by tapping Controls > Service> Owner’s Manual and select your preferred language from the dropdown menu.

This release contains minor improvements and bug fixes.

(adsbygoogle = window.adsbygoogle || []).push({});

<!–

–>

var disqus_shortname = «teslarati»;

var disqus_title = «Tesla Track Mode V2 Release Notes: Third-Party Charging, Bluetooth update included»;

var disqus_url = «https://www.teslarati.com/tesla-track-mode-v2-release-notes/»;

var disqus_identifier = «teslarati-132314»;