After successfully transplanting the first 3D-printed cornea in an animal, North Carolina company Precise Bio has recently announced the launch of a dedicated business for creating marketable, 3D-printed products for human eyes. Founded by scientists from the Wake Forest Institute of Regenerative Medicine, this company is developing bio-fabrication printers that can restore cells, tissues, and organs. Their proprietary technology, a 4D bio-printing platform, is said to resolve existing limitations presented by other bioprinters to enable more complex tissues to be engineered for transplants and treatments. By focusing on developing marketable products for the eye, the company aims to achieve rapid advancement in its field and move to overhaul the whole organ transplant system.

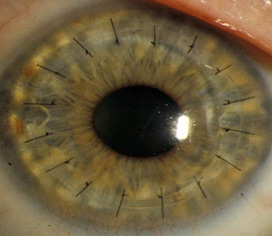

A cornea transplant with sutures still visible. | Credit: National Institutes for Health, National Eye Institute

When a cornea is damaged by disease or injury, a replacement is often needed to restore vision. Transplant surgery using donated corneas is an available solution, however, it relies on a deceased donor. While the waiting list in the United States is nearly non-existent, other countries require longer wait times, some over a year, before one is available. The Eye Bank Association of America estimates that around 10 million people suffer from corneal blindness that could potentially be restored via transplant surgery. An artificially manufactured cornea would overcome supply limitations while also contributing to the knowledge base to develop more complex organs such as hearts and livers.

The cornea is the transparent layer covering the front part of the eye that, along with the lens, accounts for about two-thirds of the eye’s optical power. It does not contain blood vessels, making it a prime candidate for bioprinting, the field of 3D printing involving biological materials. Bioprinters differ from traditional 3D printers in ways that might not be surprising given their name. Instead of heated filament applied in layers on a plate to build an object, layers of cells and biocompatible materials are printed to form tissue. Along with a lack of blood vessels, the layered structure of the cornea also makes it well suited for bioprinting.

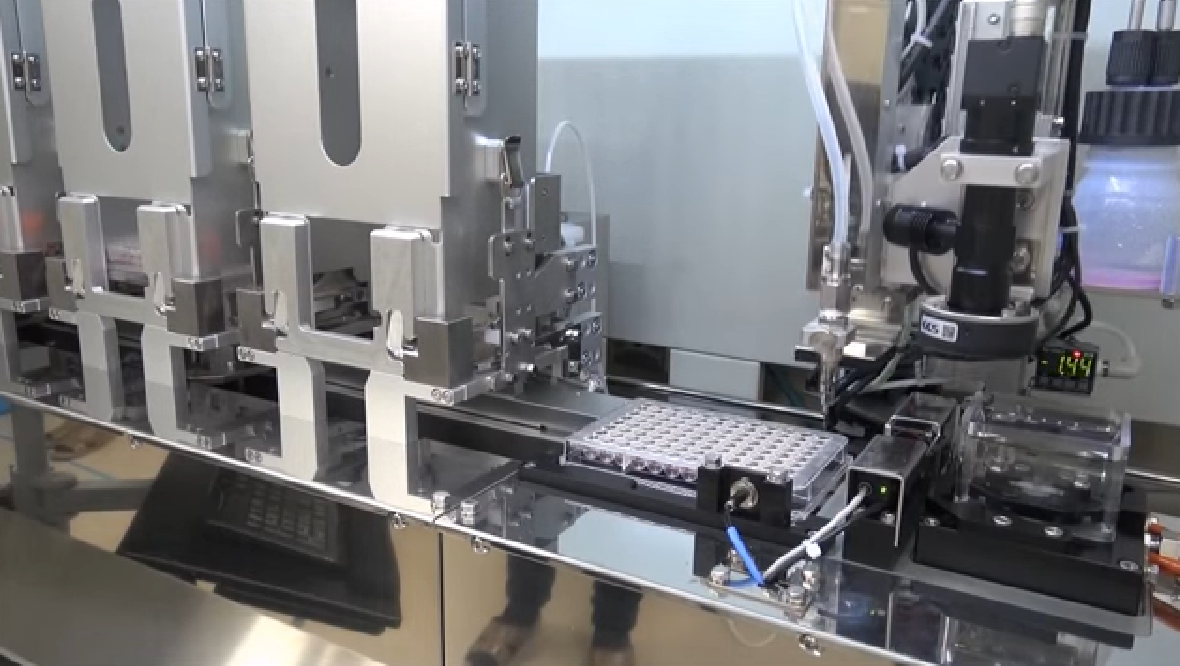

Precise Bio refers to its printing technique used for the corneas and other biomaterials as “4D” over the usual “3D” label due to the curing stage for the printed cells. The fourth dimension referred to is time needed, 10-14 days specifically, for the bio-printed cells and fibers to connect themselves together for biological operation in a bioreactor that keeps them warm for the duration. Aryeh Batt, Precise Bio’s CEO, summarized this step in an interview with IEEE Spectrum: “Essentially, the biology does the work, but you have to put them in the correct environment to make it happen.”

Initial animal safety studies for the corneal transplant have already been completed, and now the company must clear some additional hurdles to begin human testing. One of the major proofs for Precise Bio will be the demonstration of normal behavior of the bio-printed products. For example, during production using the 3D/4D printer, the printed cells grow rapidly into the form needed in a way that does not occur in a normal eye. The company will have to demonstrate in clinical studies how this process is controlled and stopped before transplant.

The field of 3D bioprinting is a research area receiving a significant amount of attention due to its potential for developments in tissue engineering, drug delivery, and cancer studies. In fact, hundreds of scientific articles were published on the topic this year alone. As with most new technology, however, the challenge of moving a development out of the laboratory and into the consumer marketplace is significant, but Precise Bio hopes to meet it head on with its new dedicated business.

For more on bioprinting, watch the below Tedx Talk by Dr. Sam Wadsworth of Aspect biosystems Ltd.